4GKW-AXplus-DW 1.8/3KV Dual Wall Single Core

Applications :

- Single core power and control cable designed for protected, fixed installation inside and outside railway vehicles for connecting fixed and moving parts in direct current and alternating voltage technology,especially converter technology.

Standards :

- BS 6853 -1a

- DIN 5510-1 1-4

- NFF 16-101 F0

|

|

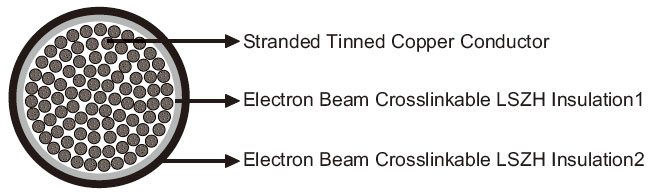

Construction :

- Conductors : Circular Class 5 stranded tinned copper to IEC60228/VDE 0295.

- Insulation1 : Electron beam crosslinkable LSZH compound.

- Insulation2 : Electron beam crosslinkable LSZH compound.

Electrical Characteristics at 20 °C :

-

Nominal Conductor Cross Section mm² 1.0 1.5 2.5 4.0 6.0 10 16 25 35 50 Maximum Conductor Resistance Ω/km 20.0 13.7 8.21 5.09 3.39 1.95 1.24 0.795 0.565 0.393 Voltage Rating KV 1.8/3.0 -

Nominal Conductor Cross Section mm² 70 95 120 150 185 240 300 400 Maximum Conductor Resistance Ω/km 0.277 0.21 0.164 0.132 0.108 0.0817 0.0654 0.0495 Voltage Rating KV 1.8/3.0

Mechanical and Thermal Properties :

- Minimum Bending Radius : 4xOD (Static); 6xOD (Flexing).

- Temperature Range : -60℃ ~+120℃ (Static); -40℃ ~+90℃ (Flexing).

- Short Circuit Temperature : +280℃.

Dimensions and Weight :

| No. of cores& Nominal Conductor Cross Sectional Area No.×mm² |

Number and Nominal Diameter of Strands No./mm |

Nominal Insulation Thickness mm |

Nominal Overall Diameter mm |

Nominal Weight kg/km |

| 1×1.0 | 32/0.20 | 0.7 | 2.8 | 17 |

| 1×1.5 | 30/0.25 | 0.8 | 3.2 | 23 |

| 1×2.0 | 32/0.20 | 0.9 | 3.55 | 28 |

| 1×2.5 | 50/0.25 | 0.9 | 3.70 | 34 |

| 1×4.0 | 56/0.30 | 1.0 | 4.45 | 53 |

| 1×6.0 | 84/0.30 | 1.1 | 5.05 | 74 |

| 1×10 | 80/0.40 | 1.2 | 6.35 | 118 |

| 1×16 | 126/0.40 | 1.5 | 8.3 | 180 |

| 1×25 | 196/0.40 | 1.8 | 10.2 | 274 |

| 1×35 | 276/0.40 | 2.0 | 11.4 | 379 |

| 1×50 | 396/0.40 | 2.2 | 13.6 | 550 |

| 1×70 | 360/0.50 | 2.1 | 15.6 | 730 |

| 1×95 | 475/0.50 | 2.3 | 17.3 | 940 |

| 1×120 | 608/0.50 | 2.4 | 19.6 | 1180 |

| 1×150 | 756/0.50 | 2.6 | 21.9 | 1510 |

| 1×185 | 925/0.50 | 2.8 | 23.8 | 1802 |

| 1×240 | 1221/0.50 | 2.9 | 26.8 | 2290 |

| 1×300 | 1525/0.50 | 3.0 | 29.7 | 2928 |

| 1×400 | 2013/0.50 | 3.4 | 35.8 | 4040 |

|

|

|

|

|

|

Impact Resistant |

Highly Flexible |

Cold Resistant |

Low Temperature Resistant |

Soldering Heat Resistant |

IRM 903 Fuel Oil Resistant |

|

|

|

|

|

|

|

IRM 902 Mineral Oil Resistant |

UV Resistant |

Ozone Resistant |

Corona Resistant |

Acid and Alkali Resistant |

Abrasion Resistant |

Low Toxicity |

|

|

|

|

|

Flame Retardant NF C32-070-2.1(C2) IEC 60332-1/EN 50265-2-1 |

Fire Retardant NF C32-070-2.2(C1) IEC 60332-3/EN50266 |

Zero Halogen IEC 60754-1/NF C20-454 EN 50267-2-1 |

Low Smoke Emission IEC 61034/NFC20-902 EN 50268/NF C32-073 |

Low Corrosivity EN 50267-2-2/NF C32-074 IEC 60754-2/NF C20-453 |